Roedean Crescent

3D Survey Model for Curved Glass Installation

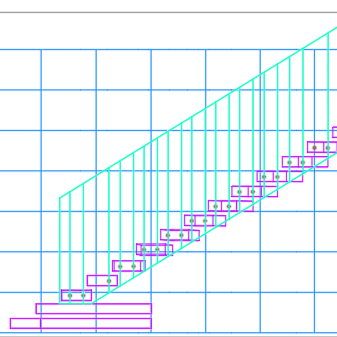

Metra Surveying Ltd was engaged by IQ Glass to develop a precise and fully detailed 3D Model for the refurbishment of a new staircase located at Roedean Crescent.

This project was distinctive in that the client required Metra to produce a 3D Model both before and after installation to conduct a comprehensive post-installation quality assurance review. The 3D Model needed to incorporate the existing curved glass handrail—an architectural feature central to the staircase design. Owing to the highly bespoke geometry of both the staircase and the handrail, the creation of an accurate and reliable 3D Model was essential for capturing the extensive and intricate spatial data present on site.

As is common with refurbishment projects, the site presented challenges concerning visibility, accessibility, and general workability. Careful planning of site access and adequate area clearance was therefore critical to obtaining the necessary data. To collect all information required for the development of the 3D Model, Metra employed advanced 3D laser scanning technology. This approach optimised on-site efficiency while ensuring a complete and precise representation of the existing conditions. Leica HDS laser scanners were utilised to capture high-quality point-cloud data, which was subsequently processed on a floor-by-floor basis to generate the final 3D Model.

3D Laser Scanning

3D Modelling in CAD

Services

Scope of Works

Establishing Control:

The workflow commenced with the establishment of a robust survey control network using the Leica TS16 total station. This step ensures accurate positioning and provides a consistent coordinating system to support all subsequent layout, stakeout, set-out, and 3D Model production activities.

3D Laser Scanning:

To overcome the typical challenges of refurbishment sites—limited access, tight spaces, and unclear details—we relied on high-performance 3D laser scanning. Using Leica HDS scanners, we captured millions of accurate data points and transformed them into detailed point clouds for the 3D Model.

3D Modelling:

Once scanning was complete, our CAD specialists processed the point cloud data and developed a precise, fully detailed 3D Model. Every measurement, angle, and curve was captured to support the client’s design and installation requirements.

Results & Benefits

Increased Efficiency:

3D laser scanning significantly accelerates data collection while enabling the integration of supplementary information that may assist the client in future design work. This method allows for the creation of a 3D Model with whatever level of detail is required, from general arrangement to highly complex geometric components.

High Precision and Accuracy:

3D laser scanners capture millions of data points within minutes, supporting the creation of 3D Models that accurately represent complex surfaces and architectural forms. Such precision is particularly valuable for intricate refurbishment projects. The final 3D Model for this project achieved a tolerance of approximately 5 mm, thereby facilitating the client’s detailed design and installation processes.

Custom-Made Task:

Each project presents unique constraints and requirements. Maintaining clear communication between the client, the site team, and Metra’s technical staff ensured that the most appropriate tools and methodologies were applied to produce a tailored 3D Model that fully met project needs.

Non-Contact Technology:

Because 3D laser scanning is non-contact, it allows data to be safely collected in environments that may be hazardous or difficult to reach, such as elevated or unstable structures. For this project, producing both a pre-installation and post-installation 3D Model was essential for comparative assessment and for delivering a detailed analysis of the changes and outcomes.

Improved Analysis:

The resulting point clouds contained rich geometric data, capturing dimensions, contours, and spatial relationships across the staircase environment. This level of detail enabled the creation of precise 3D Models of complex elements that would have been laborious, challenging, or impractical to measure manually.

Conclusion

In summary, 3D laser scanning provides a rapid, highly accurate, and inherently safe method for capturing complex spatial data. This advanced technology supports the efficient production of precise 3D Models that are suitable for a wide range of analytical, design, and conservation purposes. Its versatility makes it an invaluable tool across industries including construction, architecture, manufacturing, and heritage preservation. By delivering exceptional detail while reducing the risks associated with traditional surveying methods, 3D laser scanning is reshaping the way projects are documented, planned, executed, and maintained.