Buckingham Palace Road

Digital Layout with HP SitePrint

3D Laser Scanning

Digital Set Out

Robotic Printing

Construction Layout

Services

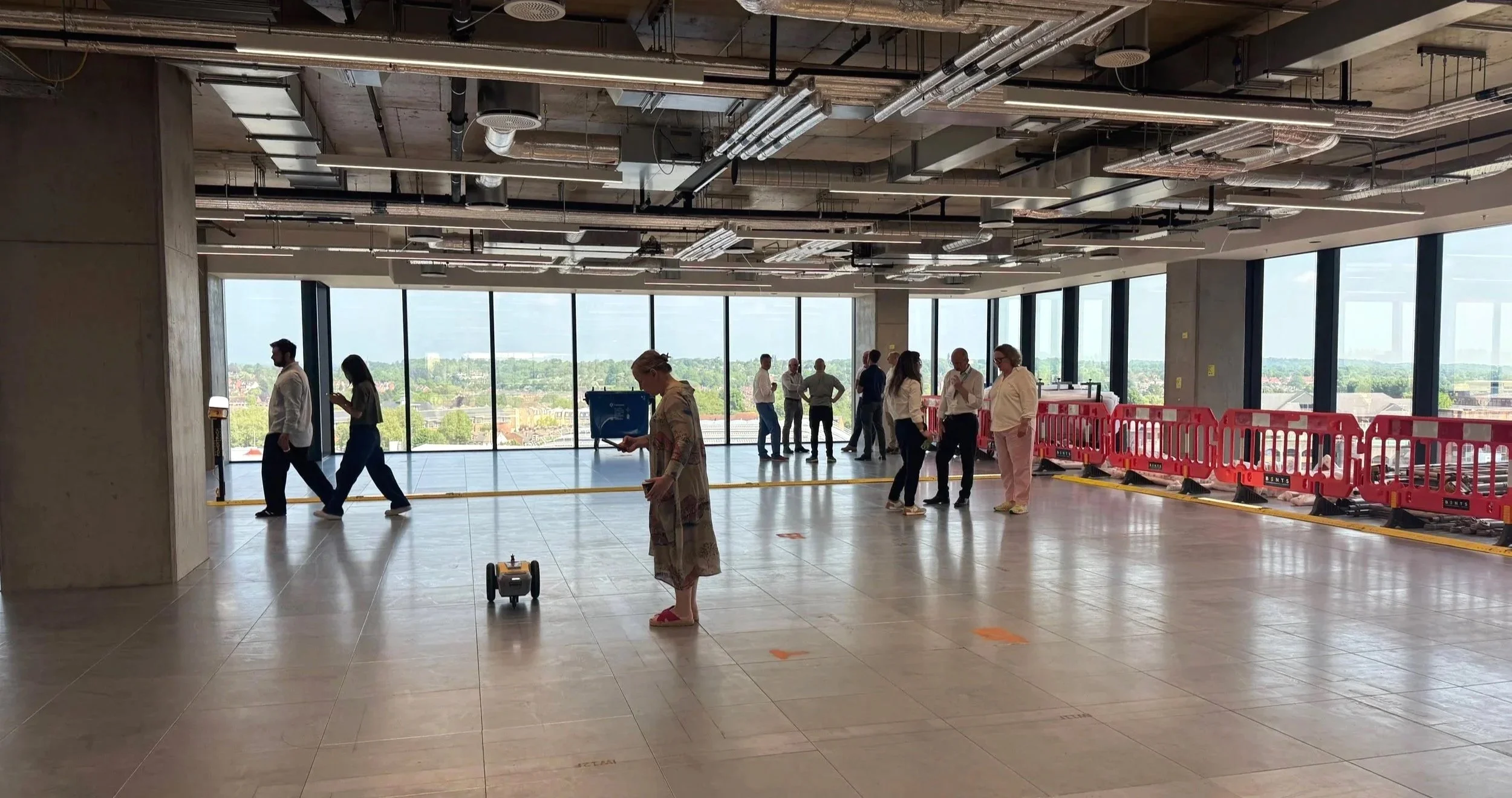

Metra was appointed by IDL to deliver a full digital set out and laser scanning workflow for the refurbishment of Level 4 at Buckingham Palace Road, London. The project required highly accurate coordination between architectural partitions and a detailed lighting design. To achieve this, Metra combined 3D laser scanning, a project-specific control network and robotic layout printing using HP SitePrint. This integrated approach provided a precise, clash-free printed layout directly on the slab, improving efficiency and certainty during early construction activities.

Scope of Works

IDL required a layout solution that delivered: high-accuracy as-built data before construction; a reliable and repeatable digital set out / stake out process; clear separation between architectural and MEP layouts; reduced reliance on manual marking; and enhanced trade coordination to avoid clashes during fit-out. Metra’s workflow ensured that all printed lines were aligned to true site conditions, improving both layout quality and programme certainty.

Workflow

3D Laser Scanning:

Metra carried out a full 3D laser scan of Level 4 to capture accurate as-built geometry. This ensured the design reflected existing conditions, identified structural variances early and guaranteed that all printed layout lines would be positioned correctly. Laser scanning significantly reduces risk during complex construction works by eliminating reliance on outdated or assumed information.

Control Network Installation:

A robust internal control network was installed and verified against the main building grid. This allowed precise robotic printing, reliable repeatability for future stake out operations and consistent positioning throughout the fit-out programme.

CAD/BIM Preparation:

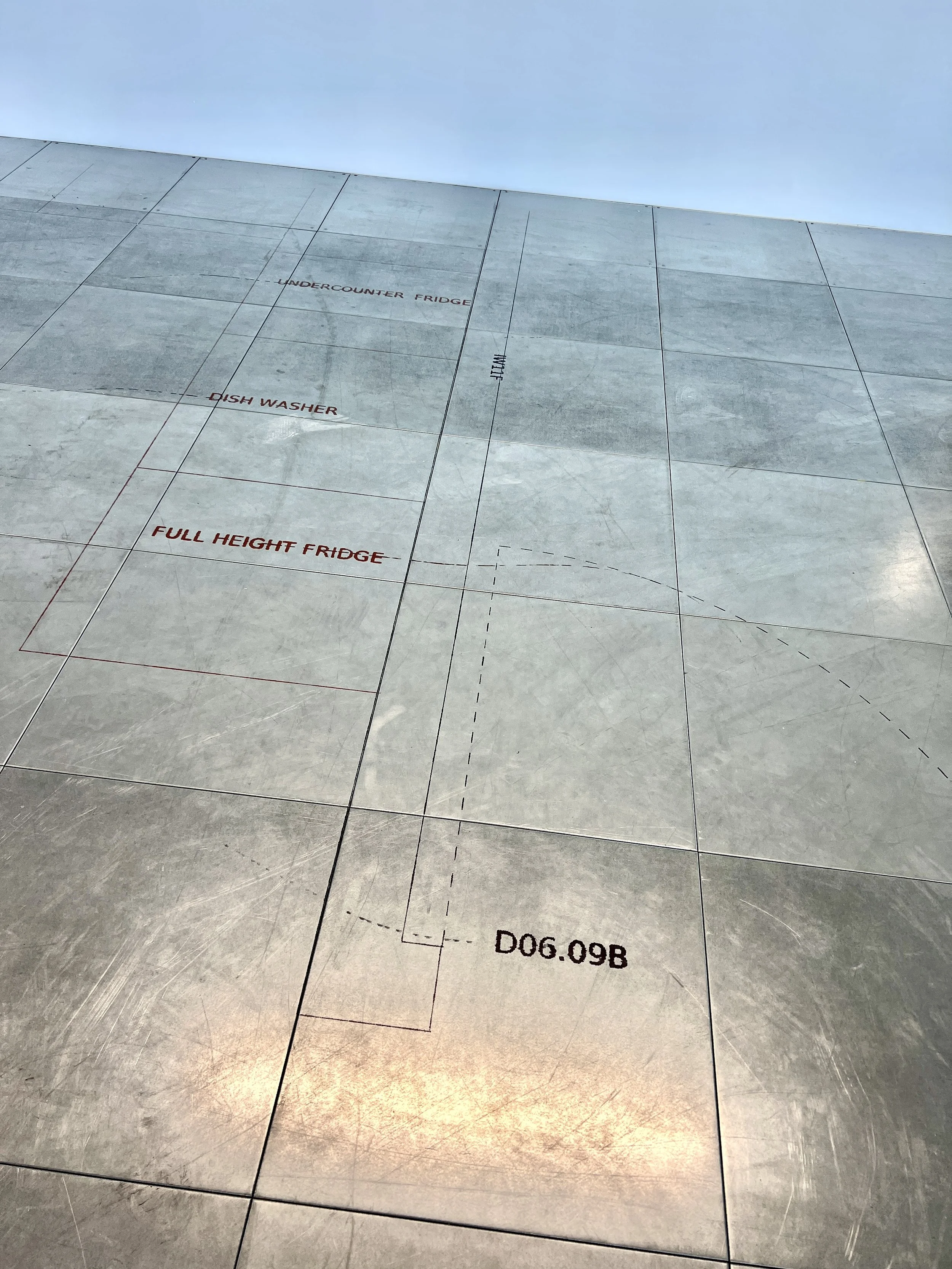

IDL’s design was optimised for digital layout. Geometry was cleaned, relevant layers isolated and colour-coding applied to support a clear and efficient printing sequence. This ensured the HP SitePrint robot could translate BIM data directly into accurate lines on the slab.

Robotic Printing with HP SitePrint:

Using HP SitePrint, tracked by a Leica TS16 total station, Metra printed the architectural and lighting layout directly onto the floor. Black ink was used for partitions, walls and doors, while red ink marked lighting fixtures, switching and electrical points. This colour-coded approach provided immediate clarity to all trades and significantly improved early-stage coordination. Robotic printing replaced traditional manual set out, delivering faster output and consistent accuracy across the entire floor plate.

Verification & On-Site Support:

Throughout the printing process, Metra carried out accuracy checks against the control network. Sequencing was coordinated with IDL to maintain safe access and avoid disruption to ongoing site activity.

Results & Benefits

Accurate set out backed by laser scanning: The layout was printed based on verified as-built conditions, reducing rework and improving construction certainty.

Improved trade coordination: Colour-coded printing helped partitioning and electrical teams understand their layouts instantly and prevented clashes.

Faster, more reliable construction printing: HP SitePrint offered rapid, precise set out, reducing labour hours and manual error.

Reduced rework: The combination of laser scanning and robotic printing ensured inconsistencies were resolved before construction began.

Future-proof layout: The installed control network allows IDL to maintain consistent accuracy for ongoing works throughout the project.

Conclusion

The Buckingham Palace Road project demonstrates how combining laser scanning, digital set out and robotic printing can transform early-stage construction. Metra’s workflow provided IDL with a clear, accurate and highly coordinated slab layout that supported smoother delivery and reduced programme risk. This project highlights how digital layout technologies are becoming a practical and reliable asset across modern UK construction.