As-built Survey for an Eighteen-Storey Tower

Saxon Wharf, London

Laser Scanning

Site Control

As-built Surveys

Services

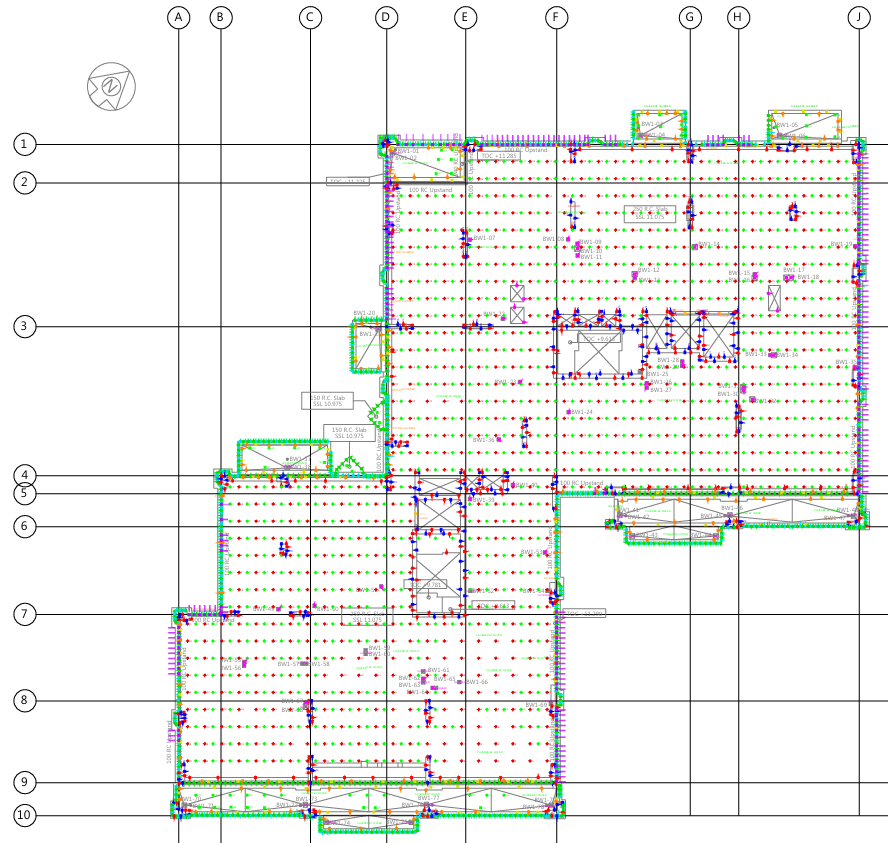

Metra Surveying was engaged by Higgins Partnership to deliver a high detail As-Built survey to verify and document how the project was built in the field, compared to the original design plans.

As with most As-built survey projects, the site presented some challenges in terms of clarity and access. Proper planning for site access and area clearance was essential to gather the necessary information. To efficiently capture all the required data for the As-built drawings, we utilized 3D laser scanning technology. This method allowed us to save time on-site while ensuring a comprehensive and precise representation of the existing conditions. We used Leica HDS laser scanners to collect high-quality point cloud data, which was processed floor by floor to create an accurate As-built survey.

Metra surveyed the building in his entirety, with a total of 18 floors for both external and internal scanning. The result was a set of highly detailed and accurate As-built survey drawings for each floor, enabling seamless design and construction planning.

Scope of Works

Meeting with the Client:

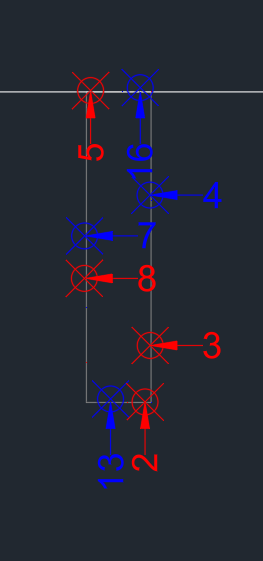

As with any large-scale project, the initial step involves meeting with the client to discuss the specific survey requirements and identify any potential challenges, review the deliverables and ensure alignment on expectations. Once the first floor was scanned and processed, the client had the opportunity to review the data, ask for further clarification, and request additional information on any areas of interest. On this project, our client requested the As-built survey drawing to include detailed dimensions and spot levels, including accurate measurements on every side of structural columns: a level of detail that would be impracticable with traditional survey techniques.

Establishing Control:

The workflow started with the setup of the survey control network per floor using the Leica TS16 total station to ensure accurate positioning and provide a reliable coordinate system for all subsequent layout, stakeout, and set-out work.

3D Laser Scanning Process:

Once the control points and datums have been verified and established on-site for each level, our engineer can proceed with the 3D laser scanning process. To ensure the highest level of precision, we utilize the Leica HDS laser scanners, specifically the P-series models. The engineer ensures that every element, as outlined in the project requirements, is thoroughly captured by the scanner for accurate processing by our team.

High detail As-built Survey drawings:

Upon completion of the scanning, the collected data is processed to generate a highly precise 3D point cloud that contains all the information gathered on-site. The CAD engineer then analyses the point cloud, extracting the relevant details necessary for the project, ensuring that all design and construction requirements are met with accuracy. Thanks to prior meeting and agreement, the CAD engineer can now produce the As-built Survey drawing tailored for this project.

Results & Benefits

Exceptional Speed:

3D laser scanning significantly accelerates the process of gathering information, while also enabling us to incorporate any additional details that may be useful to the client in the future. It allows us to generate As-built Survey drawings of the structure with any level of detail required.

High Precision and Accuracy:

3D laser scanners capture millions of data points in a short amount of time, enabling highly accurate measurements of complex shapes and structures. This level of precision is essential for more intricate projects that require detailed information or involve challenging surfaces. The resulting As-built Survey drawings had up to millimeter-accuracy, which facilitated the design and installation required.

Custom-made task:

Each project is unique and comes with its own set of challenges. Therefore, it is essential to maintain clear communication and a continuous exchange of information between the client, site, and our team. This ensures that the most suitable tools and methods are selected to achieve the best results, tailored to meet the specific requirements of the project.

Non-contact technology:

Since 3D laser scanning is a non-contact technology, it can be used to safely capture data from hazardous or hard-to-reach environments, such as elevated or unstable structures, without putting personnel at risk.

Improved Analysis:

The resulting 3D point clouds provide rich data, capturing not only dimensions but also geometric features and spatial relationships within the scanned environment. This enabled the creation of precise As-built Survey drawings of complex elements, which would have been both challenging and time-consuming to measure manually.

Conclusion

In summary, 3D laser scanning provides a faster, more accurate, and safer method for capturing detailed spatial data. This advanced technology enables the efficient collection of precise measurements, which can then be used for a wide range of applications, including analysis, design, and preservation. Its versatility makes it invaluable across numerous industries, from construction and architecture to manufacturing and heritage conservation. By offering an unprecedented level of detail and minimizing the risks associated with traditional surveying methods, 3D laser scanning is transforming the way projects are planned, executed, and maintained.